Hotline: +86-311-83655628

E-mail: lanyutech@163.com

Tel: +86-311-83655628/83655580

Fax: +86-311-83620781/83619698

Contact: Zhangli

Mobile: +86-13930119603

Add: Xinhua Road No. 165, Shijiazhuang City, Hebei Province, China

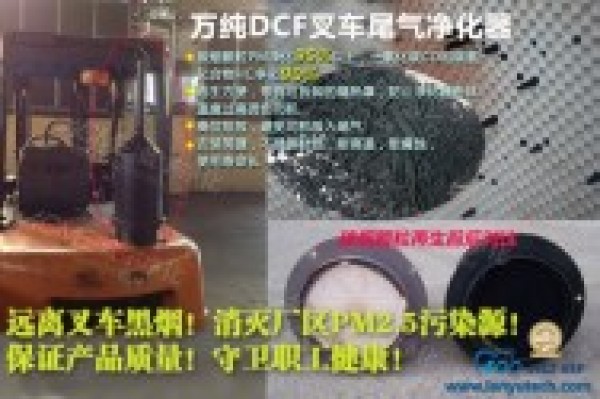

Figure 1 carrier regeneration temperature furnace

3. the principle

High temperature regeneration principle:

My company to configure a high-temperature furnace to diesel exhaust purifiers, make soot particle combustion evaporation.

Because diesel exhaust into the side of the purification unit, clean the exhaust gas is discharged after purification from the other side, after a period of time, DPF soot particles down interception clog pores in its surface more and more, it will cause the ventilation quantity is small engine back pressure, purifier gauge will show a back pressure data, when the DPF surface intercept of PM particles reach a certain number, we need to be cleaning DPF regeneration. Under normal operating speed and load of the diesel engine, the exhaust temperature is generally 250 ~ 500 ℃, and lighted particles is generally 550 ~ 600 ℃, rely on diesel engine exhaust gas temperature, it is difficult to trap regeneration. To trap regeneration must be reduced ignition particulate or increase exhaust gas temperature. Then we use high-temperature furnace for heating the filter, the

Particulate Filter material on the burn off, the device is set to the combustion temperature 700 ℃, the carrier is maintained at a high temperature oven for 3-4 hours, and then close the high-temperature furnace, the furnace temperature was lowered to room temperature to be removed after the carrier, and finally with high-pressure air pump for cleaning the carrier until the carrier sintering soot cleaning after a clean, complete regeneration.

4.the reproducing apparatus cost

The actual demand, recommend using a carrier can purify two electric kilns, electric furnace space of about 0.06 m3, the reference price (yuan) eight thousand dollars. Electric furnaces using 4--5 years, the need to replace the heat source, electric furnace body life of more than 10 years.